3D Systems

3D Systems is a global additive manufacturing solutions company that offers new and optimized digital design and production workflows to enhance healthcare simulation capabilities and competitiveness. Headquartered in Rock Hill, South Carolina, the company’s solutions include a variety of digitization, design, manufacturing, inspection and management features. Combining these features, 3D Systems’ integrated solutions are able to utilize materials, software, 3D printing and expert services to transform and revolutionize the realm of 3D printing. Today, these professional-grade online 3D printing and manufacturing services empower designers and engineers to create, iterate and produce quality parts directly from digital 3D files.

3D Systems’ end-to-end POC solution works to seamlessly integrate into healthcare workflows, as well as anatomic modeling and virtual anatomy services. The company offers a large range of 3D printing technologies cleared for manufacture of diagnostic-quality physical models across a wide range of healthcare specialties. Buying software and hardware from a single source, such as 3D Systems, is meant to give users peace of mind that the software and hardware is guaranteed to work together.

With this guarantee, users are able to deliver innovative new product designs and build complex parts easily and without limitations. Through the company’s 3D scanning platform, they can additionally create digital 3D data of the real world to enable rapid design, engineering, prototyping, special effects, location surveys and more.

Sponsored Content:

Users can also create patient-specific anatomic models for pre-operative surgical planning and diagnostic use, review patient anatomy, preplan surgeries using virtual reality and choose from a wide variety of materials to 3D print full-color, biocompatible and sterilizable anatomic models. In addition to increasing overall healthcare worker preparedness, these tools can simultaneously elevate patient safety.

In 2014, 3D Systems acquired surgical simulator manufacturer Simbionix for $120M. “Simbionix is a perfect match for our healthcare business and its powerful technology, products, channels and domain expertise expands our 3D healthcare capabilities from the training room to the About 3D Systems operating room, and extends our first mover advantage in this fast growing vertical,” said Avi Reichental, President and Chief Executive Officer, 3D Systems. In addition to synergistic technology and products, Simbionix brings to 3DS global sales channels and deep clinical relationships to accelerate the adoption of best medical practices, to advance clinical performance, and to optimize procedural outcomes. The company’s products can be found in simulation centers, hospitals, colleges and other educational facilities in over 60 countries.

History of 3D Systems

3D Systems was co-founded in 1983 by the inventor of 3D printing, Charles “Chuck” Hull. Born from a “spark of inspiration,” 3D Systems has bridged the gap between such inspiration and innovation by connecting customers with the expertise and digital manufacturing workflow required to solve business, design and engineering problems.

Sponsored Content:

Since the 1980’s, 3D Systems has grown into an international 3D solutions company. From digitization, design and medical simulation through manufacturing, inspection and management, the company’s comprehensive portfolio of technologies provides a seamless and customizable workflow. This workflow is designed to optimize products and processes while accelerating outcomes.

With advanced hardware, software and materials, as well as on demand manufacturing services and a global team of experts, 3D Systems is on a mission to transform businesses through manufacturing innovation. Moving forward, the company plans to continue to connect customers with the solutions they need to transform their business through their own manufacturing innovation.

Adding to the company’s powerful technology, products, channels and domain expertise, 3D Systems acquired the 3D virtual reality surgical simulation and training company, Simbionix, in 2014. According to 3D Systems, the acquisition of Simibionix’s synergistic technologies was done with the hope to accelerate the creation of end-to-end platforms for 3D simulation, training, virtual surgical planning and surgical simulation and the guiding and delivery of 3D printed procedures and devices.

Click Here to Connect to Leading Healthcare Simulation Vendors Like 3D Systems

Sharing 3D Systems’ uses and capabilities with potential clients, company solutions have been presented at a variety of clinical simulation conferences, exhibitions and shows, such as those hosted by SimGHOSTS, INACSL, ASPiH, SESAM, and the International Meeting for Simulation in Healthcare (IMSH) from the Society for Simulation in Healthcare (SSiH).

3D Systems Products and Solutions

3D Systems’ 3D printers are made from several materials including plastic, elastomer, composite, wax, metal, biocompatible and more material types. The extensive and versatile portfolio of 3D printing materials addresses a wide range of applications and performance characteristics in additive manufacturing.

Of the metal printers, the DMP Factory 500 Solution offers scalable metal additive manufacturing for seamless large parts. The DMP Flex 350 is a robust metal 3D printer for 24/7 part production, and the DMP Factory 350 is a robust, high-quality metal AM with integrated powder management. The DMP Flex 100 is an affordable, precise metal 3D printer for the finest features and thinnest walls.

One plastic 3D printer, the Figure 4, delivers ultra-fast additive manufacturing technology with systems that offer the expandable capacity to meet present and future needs. With access to a range of innovative materials, Figure 4 enables tool-less alternatives to traditional injection molding or urethane casting processes with direct digital production of precision plastic parts, as well as ultra-fast same-day rapid prototyping.

Examples of 3D Systems metal casting printers include the ProJet MJP 2500 IC, which creates a tool-less production of 100% wax casting patterns, the ProX 800. The ProX offers print complex assemblies, custom assembly jigs and fixtures, master patterns and mass customization of production parts.

3D Systems is also working to power the “digital dentistry revolution.” This is being achieved through the company’s push for the industry-leading technologies and expertise needed for dental labs and dentists to streamline services and support desired dental outcomes.

Dental labs are now adopting 3D printing from 3D Systems to experience more efficient use of precious metals, fewer remakes and better precision though digital methods. As for metal 3D printing for dental, 3D Systems’ applied Direct Metal Printing (DMP) technology provides unlimited design flexibility with perfect passive fit.

The DMP Dental 100 can be used for Manufacturing small, dense and complex dental prostheses. With short post-processing at high productivity and high-performance software solution from dental file to production, the DMP Dental 100 can print more than 90 crowns within under 4 hours, in one single print-run.

3D Systems software is available for reverse engineering, design for manufacturing, additive and subtractive manufacturing, inspection and management. Software is produced for haptic devices as well. For example, the 3DXpert is an all-in-one integrated software to prepare, optimize and manufacture 3D CAD models. This software uses industrial metal additive manufacturing (AM). The parametric-based software streamlines a user’s process to quickly and efficiently transition from a 3D model to a successfully printed part.

Further, 3D Systems services experts are available to support users in the early phases of identifying the potential of the additive technology for a company. This support involves developing and qualifying an application and finally transferring knowledge to a user’s own manufacturing environment.

3D Systems Latest News

Utilizing Surgical Science’s MentorLearn to Manage Simulators and Improve Outcomes

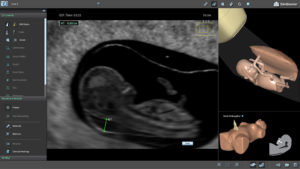

Surgical Science Launches Pediatric Simulator Add-On to Ultrasound Mentor

Latest Clinical Simulation News From Around the World | October 2021

3D Systems Announces Sale of Medical Simulation Business, Simbionix

Latest Medical Simulation Technologies Launched for IMSH 2021

13 More Simulation in Healthcare Companies to That You Need to Know About

IMSH 2020 Exhibit Hall Vendor Video Round Up

New Surgical Simulators From 3D Systems – IMSH 2019 Video Interview

3D Systems U/S Mentor Ultrasound OB-GYN Simulator Also Offers Fetus Scanning Module

Sponsored Content: